ProductsProducts

Spin Processor

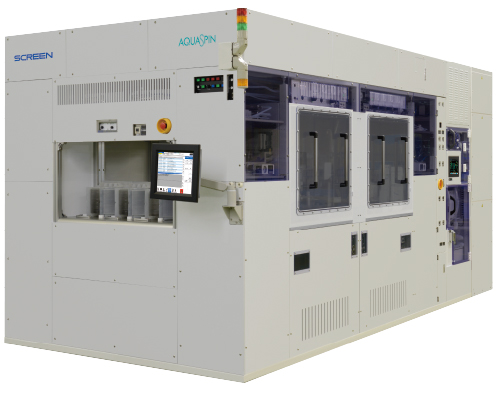

SP-2100

Wafer size 76mm ~ 200mm

Outstanding functionality and scalability easily handle emerging needs

-

1. Reliable wafer transfer using a mechanical method

The SP-2100 employs an I-LINE single path transfer system. Stable wafer transfer is achieved by a pick-and-place method of mechanical transfer with a well-established track record.

-

2. Suitable for a wide range of compound wafers

The SP-2100 is suitable for SiC, GaN, LiTaO3, and many other types of compound wafers, as well as silicon wafers. It can process a wide range of wafer sizes from 76 to 200 mm.

-

3. Processing chamber (MTC/DTC)

Multitask chamber

The SP-2100 can also perform cleaning and etching using high-temperature strong acids.Dry-task chamber

Wafers are rinsed using DIW, followed by high-speed spin drying. -

4. Suitable for metal etching processes

The SP-2100 can perform etching with high reproducibility when equipped with the optional SCREEN proprietary endpoint sensor.

-

5. A new GUI enhances usability

The SP-2100 features a new GUI and an updated control system for simple, intuitive operation.

-

6. Optional cleaning tools further expand device compatibility

Either Nanospray or Softspray is available as an optional cleaning tool, and a surface brush can also be installed for post-CMP cleaning and other processes. The SP-2100 can thus perform a wide range of cleaning processes to suit the purpose and application.

Other

-

Spin Scrubber

SS-80EX

Wafer size 100mm ~ 200mm

Advanced Scrubber Featuring the Same Stability and Reliability as the Highly Regarded SS Series.

-

Spin Processor

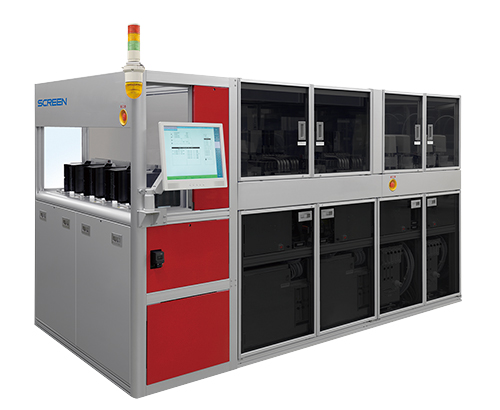

SU-2000

Wafer size 150mm ~ 200mm

Inherits High-end Single Wafer Cleaning Technology to Deliver Outstanding Cost Performance

-

Coat/Develop Track

SK-60EX/

SK-80EXWafer size 150mm ~ 200mm

Flexibility to Process a Variety of Substrates